Partnering with an anatomical model manufacturer can be one of the most cost-effective solutions for elevating medical education with the use of anatomy models. While precious practical surgical experience or patient education previously relied on cadaver models or educational lectures, instructors and other medical professionals today have the option of using a wide array of anatomy models to enhance their training and methods.

The expansion of customized anatomy models has also become a thriving area for sales professionals and medical device creators. Whatever the profession, the need for the highest quality products has become even more of a necessity. Having knowledge about what sets an anatomical model manufacturer apart from others in their industry can help with forming a successful partnership.

Factors to Consider When Choosing an Anatomical Model Manufacturer

TransparencyTransparency is a key component of an optimal manufacturing partnership. Open communication can help companies avoid partnering with a manufacturer that works with a third-party provider to purchase wholesale products from them. Direct, transparent partnerships allow companies to order customized products without the risk of specific requirements being lost in translation to outside manufacturers. It also facilitates open communication between manufacturers and consumer companies so that there are no misunderstandings about delays or other necessary product updates. |

ExperienceAn experienced anatomical model manufacturer is one that has been in the industry for decades and has advanced their products through the years to measure up to the advancements of modern medicine. Extensive experience means that a manufacturer has had ample time to learn what model characteristics best fit the various needs for the range of uses that anatomy models are purchased for. An abundance of trial and error on the market is crucial to being able to successfully meet the demands of an advancing market. |

ReputationReputation should also be considered in addition to a manufacturer’s level of experience. A distinguished anatomical model manufacturer should be well known in the industry. They should be an established leader in the field, allowing them to be easily recommended in conversation. Companies seeking to partner with a manufacturer should always research the manufacturers they’re considering to assess their reputation in the industry. |

Expansive CatalogWhen buyers partner with manufacturers, they usually do it in the hopes of purchasing all of their anatomy models from that same manufacturer. A company with an expansive catalog has the greatest likelihood of having all the necessary training resources. An extensive catalog should include a variety of models ranging from display models to training models, as well as biomechanical training models and digital anatomy. This allows multiple organizations, from teaching hospitals to medical device innovators, to have the most cost-effective route of having all of their resource needs met. |

Material OptionsVarious material options allow for anatomy models to be built that fit diverse consumer needs and facilitate surgical training at multiple educational levels. Clear model material is the standard for display models, but including a range of realistic materials like composite bone or accurate, artificial skin layers and muscle tissue is also needed for more functional training models. Solid foam or foam cortical shell options can be a more economical, durable option for functional training. Radiopaque materials allow that functionality to extend to live imaging training to broaden medical education with anatomy models. Having diverse, realistic materials also increases the chances of finding a functional, training model for any medical field. |

LocationAnatomy models require a designated amount of time to be created and delivered, and this can be an even longer process if a customized piece has been ordered. A practical purchaser would opt for a manufacturer located in a region that best eliminates prolonged delivery time and damage risks associated with extensive shipping processes like overseas flights or clearing customs. |

CustomizationCustom models allow purchasers to have a model that suits their specific needs and optimizes training potential. Manufacturers that are known as industry leaders are able to create custom models that can simulate any medical setting with the requested level of accuracy. Customization gives purchasers and instructors precise models and tools to expose their students to specific clinical challenges and give more accessibility to a higher standard of training. |

Rental OptionsRental options offer a more economical route to obtaining the necessary models and resources for training or display. For some purchases, it’s not always the most reasonable option to buy a model when it may not be needed for more than a single workshop. In other cases, it may not be within the current budget to fully purchase a model, or an instructor may prefer to test out a model to see if it fits their training curriculum. Partnering with a manufacturer that offers rental options can help provide a more cost-effective alternative, if necessary. |

These are some of the most important business factors when it comes to choosing an anatomical model manufacturer to partner with, but the search criteria should also consider the range and caliber of products being offered before making a decision.

Seeking Comprehensive Product Categories

In order to increase the likelihood of obtaining various anatomy models from the same company, purchasers should search for anatomical model manufacturers that house a range of product categories to support the different needs associated with anatomy models. Those categories should include:

Category |

Description |

Sawbones Products |

|

Display ModelsClear bone models or other custom displays are designed to showcase human or animal anatomy, as well as highlight the features of medical devices or implants if necessary. Display models increase awareness of the chosen anatomical site and can help spark innovation of devices or techniques to improve patient outcomes. |

|

|

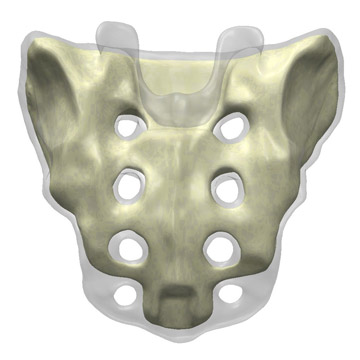

Biomechanical ModelsBiomechanical models include composite bones, blocks, sheets, and cylinders and are excellent alternative testing media to human cadaver bones. Composite bones mimic the properties of human bones to simulate load and motion scenarios for medical device development and approval. |

|

|

Orthopaedic ModelsOrthopaedic models are resilient models built to aid in diagnosis education and surgical training. They are made to be drilled, cut, and re-used for an array of teaching exercises based on student skill. Orthopaedic models can be made from materials such as foam cortical shell, plastic cortical shell, or solid foam. They can also be made to display orthopaedic fractures. These models can be made to fit any specific training need. |

|

|

Patient Education ModelsA leading anatomical model manufacturer should be able to design buildable and realistic anatomy education models, as well as curated charts to aid and demonstrative models to aid educational workshops or seminars. High quality education models are made to withstand repeated use and provoke effective communication about a specific area or condition. |

|

|

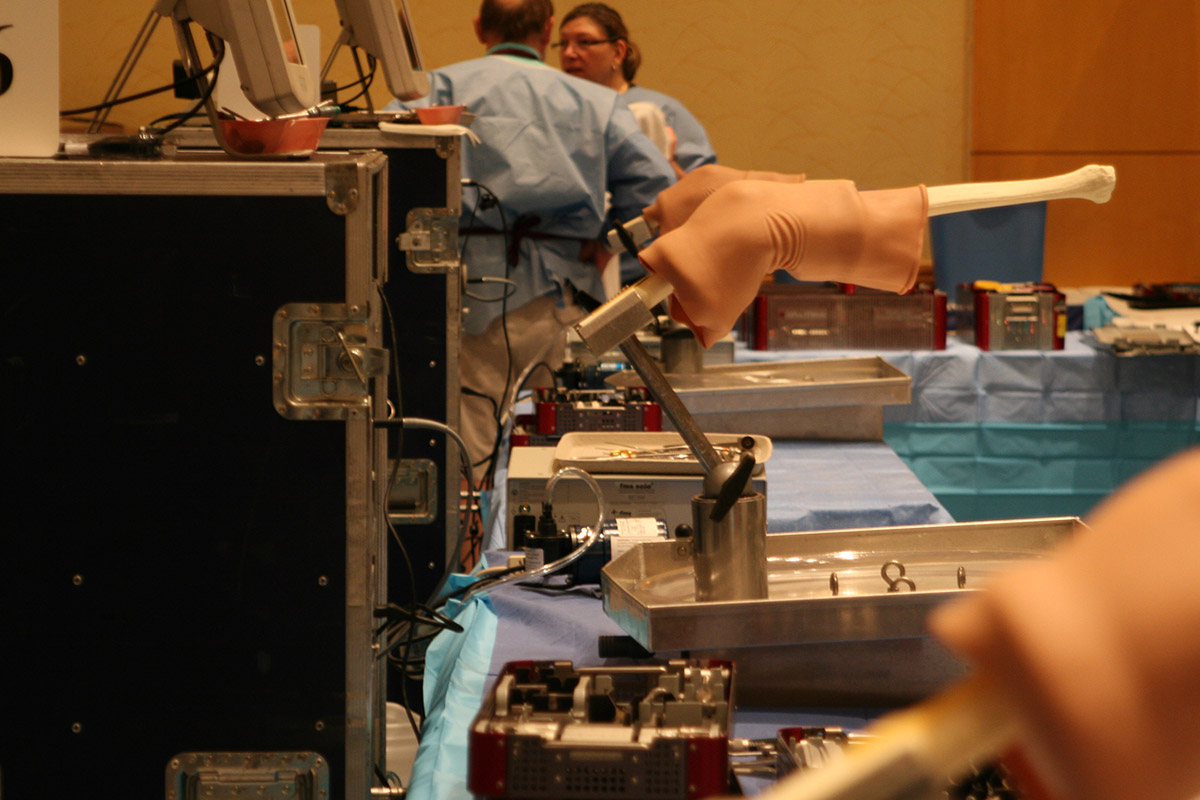

Training ModelsTraining models are designed for hands-on use in surgical skill-building and include realistic and advanced features for growing skill sets. Partnering with an innovative manufacturer can give purchasers access to a variety of models and allow them to order custom models to further elevate their training courses. These can range from realistic anatomy models to STEM education models and even accessories. |

|

|

Veterinary ModelsVeterinary products bring accessibility to practicing and perfecting veterinary surgical skills. They also offer a way to provide education for various treatments. Customization of veterinary models also brings more efficiency to surgical training and treatment planning, as well as training and demonstration for device manufacturers. |

|

|

Digital Anatomy ModelsDigital anatomy media advances training programs, studies, or workshops by giving access to computer files with high digital accuracy and a 3D view. They come in various file formats and give views of both external and internal anatomy. Digital models can also include finite element models for simulated experiments and comparisons. |

Along with the variety of models, purchasers should also research the level of advancement offered for model builds to ensure they receive quality products worth their investment.

Choosing a Manufacturer with Advanced Feature Options

Seeking the highest quality anatomy models means choosing a manufacturer that offers the most advanced model features on the market. The features most known to create the most suitable models for any training program and optimize engagement are:

- Haptic Feedback: This provides real-time responses to a trainee’s movements. It makes an alert noise when an instrument comes in contact with internal structures within the model to indicate the success or failure of a student’s decision. It is also the realistic feel of bone, tissue, cancellous, etc, and is thus an optimal choice for arthroscopic surgery and injection training.

- Composite Bone: This material mimics the composition of bone structure. It’s the most realistic replacement for evaluations involving cadaver bone. Composite bones mimic the properties of human bones, helping to easily and inexpensively simulate load and motion scenarios for medical device development and approval.

- Buildability: This quality makes model expansion possible. As trainees master one type of procedure, instructors can add on parts to increase the complexity. Models can be basic or include only internal structures--such as ligaments and muscles--that are pertinent to a procedure.

- Dual Usage: These models allow users to learn both arthroscopic and open diagnostic procedures to broaden their success in various settings. They are effective in allowing students to assess the best surgical route for different clinical injuries.

- Kinetic Accuracy: Models that offer similar kinetic motion to the joint or bone found in the human body can increase user engagement. They’re also valuable tools for orthopaedic, rheumatology, and rehabilitation lessons by showing the user both the proper movement of the joint and how that movement can be hindered by injury or disease.

- Radiopacity: Radiopaque elements in anatomy models block radiation to allow the models to undergo diagnostic imaging without damage. This is crucial for medical imaging training and helpful in guiding fracture reduction, needle placement, IM nail placement, and cortical screw placement as well as teaching how to interpret imaging results.

For the highest quality products, purchasers should always seek anatomical model manufacturers that have established themselves as industry leaders and innovators. Anatomy models have become indisputably valuable in both clinical and non-clinical environments, making it even more important that the quality of the products is sufficient enough to increase their effectiveness and provide the best return on investment.

Sawbones has been an innovating, industry leader amongst anatomical model manufacturers for over forty-five years and provides a wide array of products to meet any need. To learn more about all we have to offer, view our catalog, visit our contact page, or call (206) 463-5551