Biomechanical Materials for Precise, Repeatable Testing

Sawbones Leads The Industry With Biomechanical Products & Materials For Testing and Validation

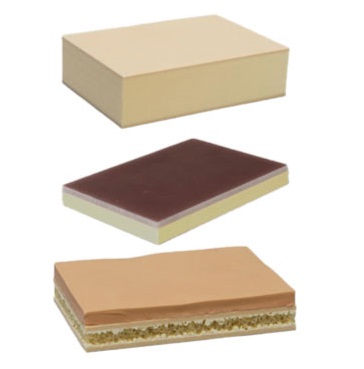

Blocks and Sheets

Rigid foam blocks are an alternative material to human cadaver bone for testing and demonstrating orthopaedic implants, instruments and instrumentation.

Sawbones blocks and sheets may be laminated or shaped for all your custom applications. We create thousands of different combinations and shapes to meet the fast paced demands of regulatory approval and sales demonstrations.

Sawbones cannot provide testing instruction.

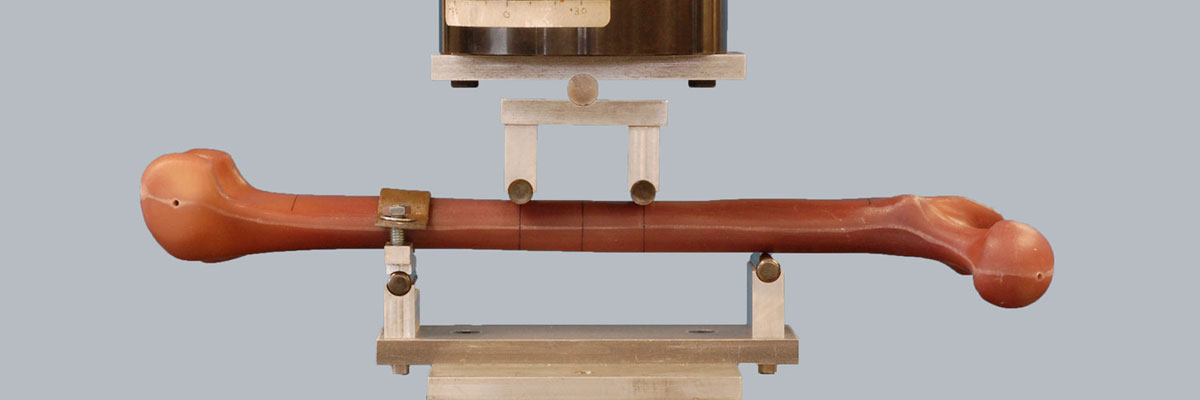

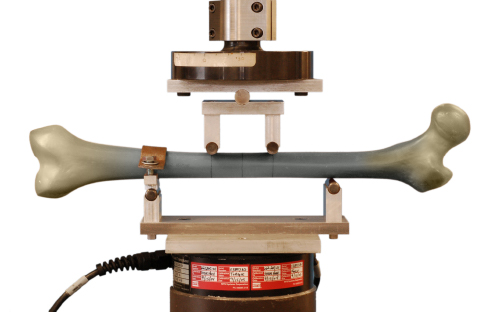

Composite Bones

Our composite bones mimic the properties of human bones to help you easily and inexpensively simulate load and motion scenarios for medical device development and approval.

Sawbones Composite Bones are used as alternative testing media to human cadaver bone. Achieve confidence in your results with repeatable performance.

Sawbones cannot provide testing instruction.

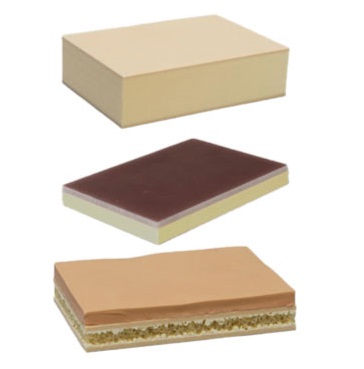

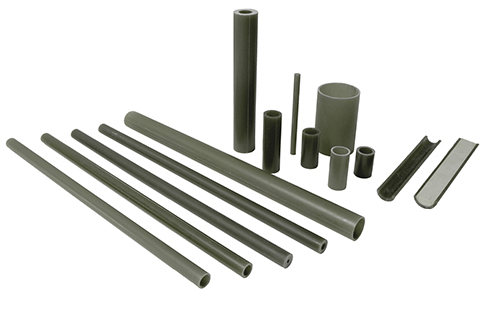

Composite Cylinders

Simulate mid-diaphyseal bone for fracture fixation testing with our hollow or foam filled composite cylinders.

Sawbones Composite Cylinders can be tailored in different sizes and materials to achieve a wide range of properties needed for testing medical devices.

Sawbones cannot provide testing instruction.

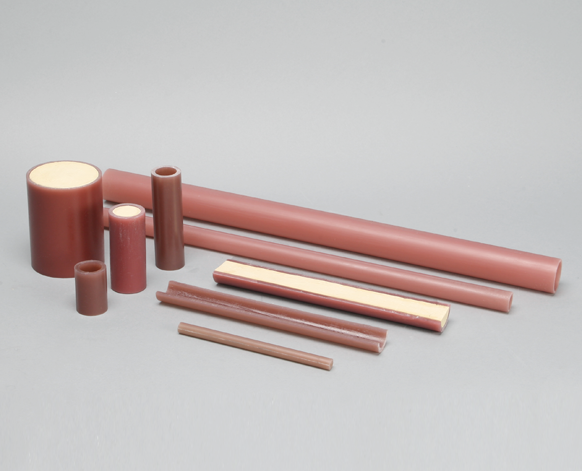

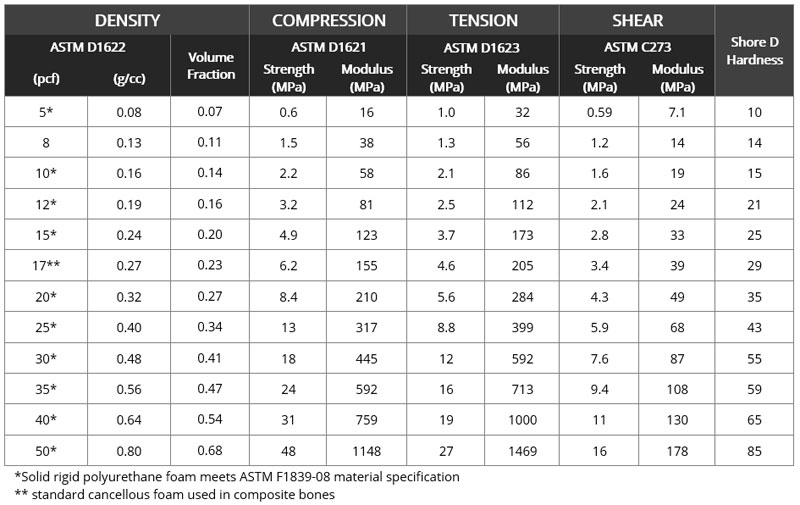

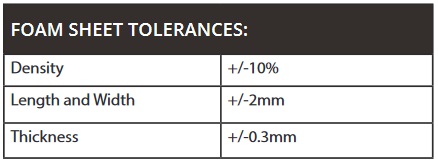

Solid Rigid Polyurethane Foam

Solid rigid polyurethane foam provides a uniform structure with only +/-10% variation in density. Material properties cover a broad range of human bone qualities allowing you to select an appropriate density for your study. This closed cell foam conforms to ASTM F-1839-08 “Standard Specification for Rigid Polyurethane Foam for Use as a Standard Material for Testing Orthopaedic Devices and Instruments” and has the largest density range available from 0.08g/cc up to 0.80g/cc (5pcf to 50pcf).

For more information see our Biomechanical Products Catalog and Biomechanical Validation Studies page.

Our foam is available in a range of sizes and densities, f rom 0.08 to 0.80 grams per cubic centimeter (5 to 50 pounds per cubic foot).

Cellular Rigid Polyurethane Foam

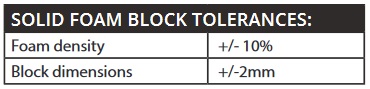

Cellular rigid polyurethane foam has larger pores to resemble cancellous bone. Cell size ranges from 0.5 to 2.0mm diameter for this primarily closed cell foam. Variation in foam density is ± 10% and is available in a range of densities from 0.12g/cc to 0.32 g/cc (7.5pcf to 20pcf).

For more information see our Biomechanical Products Catalog and Biomechanical Validation Studies page.

BLOCK SIZE: 13 cm x 18 cm x 4 cm

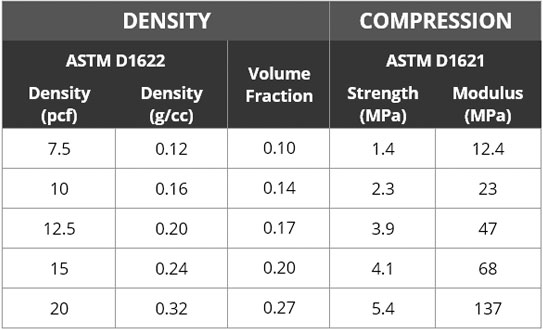

Open Cell Rigid Foam

Open cell rigid foam is a composite foam made of urethanes, epoxies and structural fillers. Cell size ranges from 1.5 to 2.5mm in diameter and is more variable than solid or cellular polyurethane foams. Variation in foam density is ±10% and is available in a range of densities from 0.12g/cc to 0.48 g/cc (7.5pcf to 30pcf).

Note: 30pcf open cell foam contains both closed and open cell walls.

For more information see our Biomechanical Products Catalog and Biomechanical Validation Studies page.

BLOCK SIZE:

13 cm x 18 cm x 4 cm

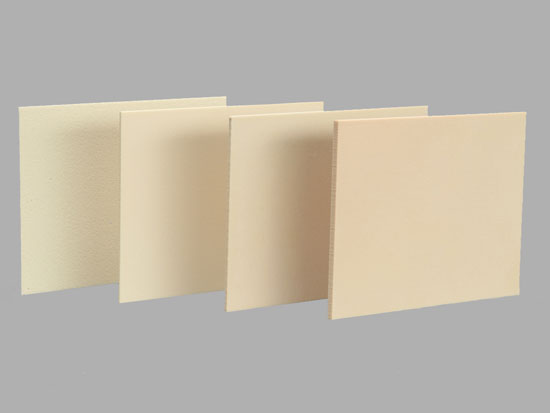

Solid Rigid Polyurethane Foam Sheets

This closed cell polyurethane foam is most commonly used for testing screw pullout, insertion and stripping torque.

For more information see our Biomechanical Products Catalog and Biomechanical Validation Studies page.

SHEET SIZE:

13 cm x 18 cm x 1 mm

SHEET SIZE:

13 cm x 18 cm x 2 mm

SHEET SIZE:

13 cm x 18 cm x 1.5 mm

SHEET SIZE:

13 cm x 18 cm x 3 mm

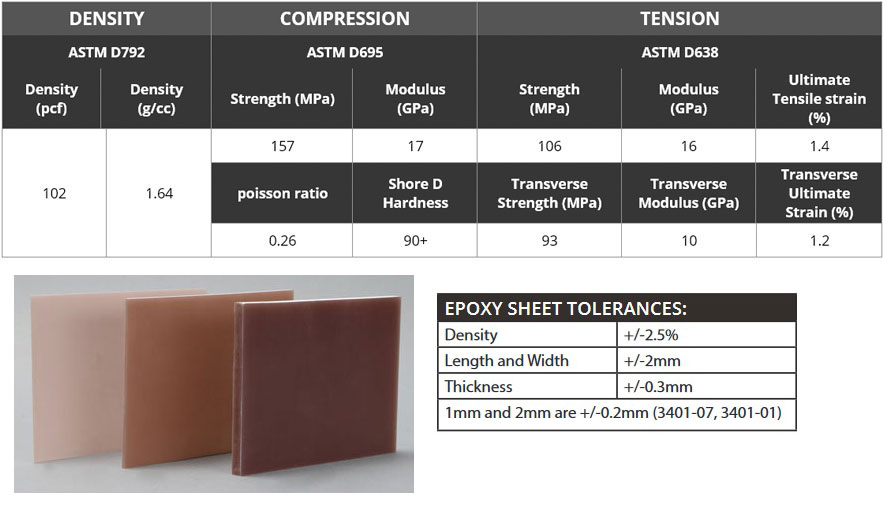

Composite Sheets (Short Fiber Filled Epoxy)

Sawbones’ unique epoxy formulation is filled with short glass fibers and used to simulate cortical bone for structural testing of fixation devices and total joint replacements. Our simulated cortical bone has a density, fracture toughness, strength, modulus and hardness all similar to cadaveric cortical bone.

This material is the cortical bone for all our composite bones - Shop Composite Bones.

For more information see our Biomechanical Products Catalog and Biomechanical Validation Studies page.

SHEET SIZE:

13 cm x 18 cm x __ mm

Rigid foam blocks are an alternative material to human cadaver bone for testing and demonstrating orthopaedic implants, instruments and instrumentation.

Sawbones blocks and sheets may be laminated or shaped for all your custom applications.

Our absolute™ bones mimic the properties of human bones to help you easily and inexpensively simulate load and motion scenarios for medical device development and approval.

Sawbones absolute™ bones are used as alternative testing media to human cadaver bone.

Sawbones cannot provide testing instruction.

MATERIALS GUIDE

absolute Sheets (Short Fiber Filled Epoxy)

Sawbones’ unique epoxy formulation is filled with short glass fibers and used to simulate cortical bone for structural testing of fixation devices and total joint replacements. Our simulated cortical bone has a density, fracture toughness, strength, modulus and hardness all similar to cadaveric cortical bone.

This material is the cortical bone for all our absolute bones.

For more information see our absolute Properties Chart and Biomechanical Validation Studies page.

Open Cell Rigid Polyurethane Foam

Open cell rigid foam is a composite foam made of urethanes, epoxies and structural fillers. Cell size ranges from 1.5 to 2.5mm in diameter and is more variable than solid or cellular polyurethane foams. Variation in foam density is ±10% and is available in a range of densities from 0.12g/cc to 0.48 g/cc (7.5pcf to 30pcf).

Note: 30pcf open cell foam contains both closed and open cell walls.

For more information see our Open Cell Rigid Foam Properties Chart and Biomechanical Validation Studies page.

absolute Sheets (Short Fiber Filled Epoxy)

Sawbones’ unique epoxy formulation is filled with short glass fibers and used to simulate cortical bone for structural testing of fixation devices and total joint replacements. Our simulated cortical bone has a density, fracture toughness, strength, modulus and hardness all similar to cadaveric cortical bone.

This material is the cortical bone for all our absolute bones.

For more information see our absolute Properties Chart and Biomechanical Validation Studies page.

Cellular Rigid Polyurethane Foam

Cellular rigid polyurethane foam has larger pores to resemble cancellous bone. Cell size ranges from 0.5 to 2.0mm diameter for this primarily closed cell foam. Variation in foam density is ± 10% and is available in a range of densities from 0.12g/cc to 0.32 g/cc (7.5pcf to 20pcf).

For more information see our Cellular Rigid Foam Properties Chart and Biomechanical Validation Studies page.

Open Cell Rigid Polyurethane Foam

Open cell rigid foam is a composite foam made of urethanes, epoxies and structural fillers. Cell size ranges from 1.5 to 2.5mm in diameter and is more variable than solid or cellular polyurethane foams. Variation in foam density is ±10% and is available in a range of densities from 0.12g/cc to 0.48 g/cc (7.5pcf to 30pcf).

Note: 30pcf open cell foam contains both closed and open cell walls.

For more information see our Open Cell Rigid Foam Properties Chart and Biomechanical Validation Studies page.

Solid Rigid Polyurethane Foam

Solid rigid polyurethane foam provides a uniform structure with only +/-10% variation in density. Material properties cover a broad range of human bone qualities allowing you to select an appropriate density for your study. This closed cell foam conforms to ASTM F-1839-08 “Standard Specification for Rigid Polyurethane Foam for Use as a Standard Material for Testing Orthopaedic Devices and Instruments” and has the largest density range available from 0.08g/cc up to 0.80g/cc (5pcf to 50pcf).

For more information review the Solid Rigid Polyurethane Foam Properties Chart and Biomechanical Validation Studies page.

absolute™ (Short Fiber Filled Epoxy)

Sawbones’ unique epoxy formulation is filled with short glass fibers and used to simulate cortical bone for structural testing of fixation devices and total joint replacements. Our simulated cortical bone has a density, fracture toughness, strength, modulus and hardness all similar to cadaveric cortical bone.

This material is the cortical bone for all our absolute™ bones.

For more information see our absolute™ Properties Chart and Biomechanical Validation Studies page.

Cellular Rigid Polyurethane Foam

Cellular rigid polyurethane foam has larger pores to resemble cancellous bone. Cell size ranges from 0.5 to 2.0mm diameter for this primarily closed cell foam. Variation in foam density is ± 10% and is available in a range of densities from 0.12g/cc to 0.32 g/cc (7.5pcf to 20pcf).

For more information see our Cellular Rigid Foam Properties Chart and Biomechanical Validation Studies page.

Open Cell Rigid Polyurethane Foam

Open cell rigid foam is a composite foam made of urethanes, epoxies and structural fillers. Cell size ranges from 1.5 to 2.5mm in diameter and is more variable than solid or cellular polyurethane foams. Variation in foam density is ±10% and is available in a range of densities from 0.12g/cc to 0.48 g/cc (7.5pcf to 30pcf).

Note: 30pcf open cell foam contains both closed and open cell walls.

For more information see our Open Cell Rigid Foam Properties Chart and Biomechanical Validation Studies page.

Solid Rigid Polyurethane Foam

This closed cell polyurethane foam is most commonly used for testing screw pullout, insertion and stripping torque. Solid rigid polyurethane foam provides a uniform structure with only +/-10% variation in density. Material properties cover a broad range of human bone qualities allowing you to select an appropriate density for your study. This closed cell foam conforms to ASTM F-1839-08 “Standard Specification for Rigid Polyurethane Foam for Use as a Standard Material for Testing Orthopaedic Devices. Available Grades: 5, 10, 12, 15, 20, 25, 30, 35, 40, 50

For more information review the Solid Rigid Polyurethane Foam Properties Chart and Biomechanical Validation Studies page.

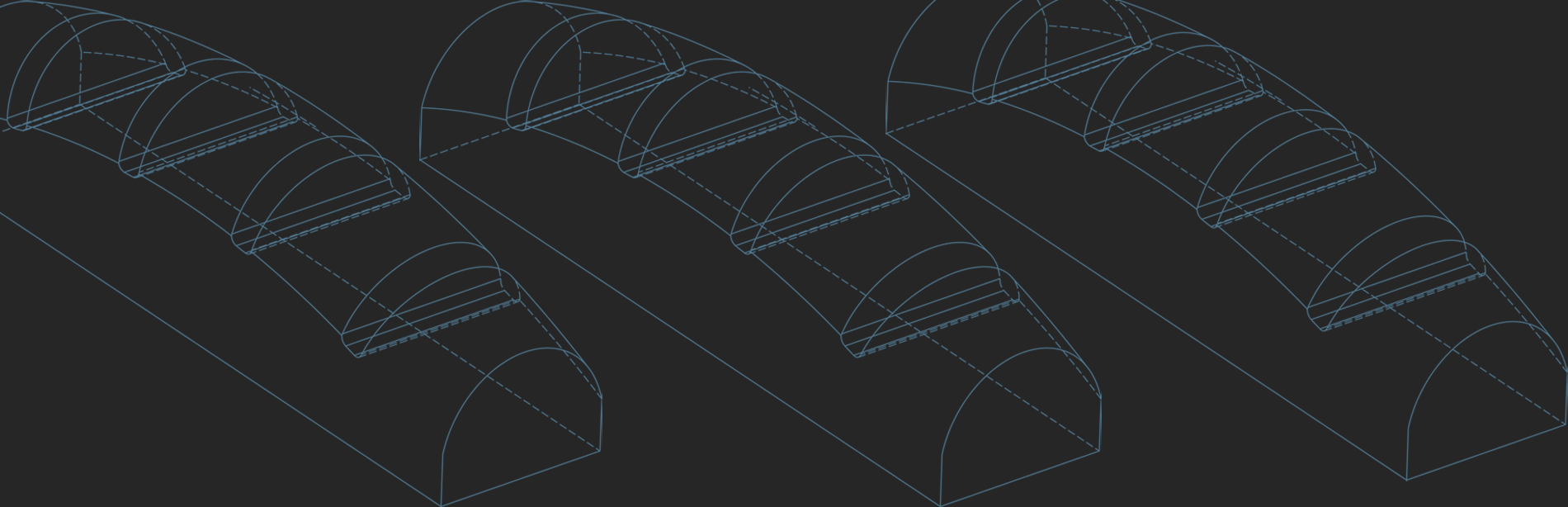

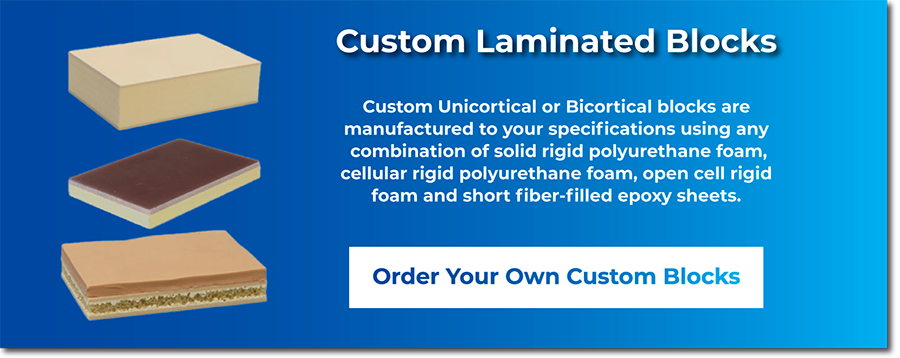

Improve your testing and validation processes with custom laminated blocks.

IMPROVE YOUR TESTING AND VALIDATION PROCESSES

WITH CUSTOM LAMINATED BLOCKS

Precision-crafted to your exact specifications, our blocks can include any combination of solid rigid polyurethane foam, cellular rigid foam, open cell rigid foam, and absolute™ sheets.

We create thousands of different combinations and shapes to meet the fast paced demands of regulatory approval and sales demonstrations.

Ensure accuracy and reliability in your research – Request your custom solution for testing and validation now!

Custom unicortical or bicortical blocks are manufactured to your specifications using any combination of solid rigid polyurethane foam, cellular rigid foam, open cell rigid foam and absolute fourth generation sheets.