Sawbones Showcase: Hip Joint Models Demonstrate Both Function and Physiology for Total Hip Replacements

The 2021 American Joint Replacement Registry (AJRR) reported that total hip replacement is the second most performed arthroplasty procedure, comprising 34.6% of all arthroplasty procedures from 2012 to 2020. The majority of orthopedic surgeons will perform both primary or first-time total hip replacement, as well as revision surgery, throughout their careers. Hip replacement’s continuing prominence in the field of joint replacement necessitates not only comprehensive training in medical school but accessibility in patient education as well.

High-quality hip joint models are perfect tools for helping both medical students and patients grasp the function and physiology central to total hip replacement procedures.

Patient Education and Medical Training for Total Hip Arthroplasty

Total hip replacement is one of the most successful and routine surgical procedures today. In spite of this, myths and misinformation still cause patients to be apprehensive about implants, recovery, complications, and other concerns. Some people fear wearing a joint implant will alter their natural gait, while others think it will limit their enjoyment of daily activities.

Moreover, patients who have never worn implants before may be averse to the idea, especially in the case of major surgery such as total hip arthroplasty. An informative explanation of the procedure along with a listening ear go a long way in furthering patient education, easing anxieties, and building professional relationships within the healthcare setting. A more complete understanding of the ins and outs of the operation also contributes to patient cooperation regarding wound care, therapy, and pain management after surgery.

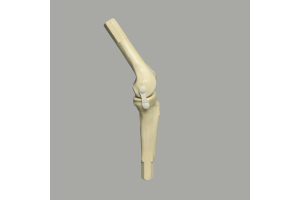

In the case of medical students, having a comprehensive physiological and technical understanding of total hip arthroplasty will better prepare them to anticipate patients’ questions similar to those outlined above. A high quality and detailed hip joint model such as the one below can be used to demonstrate accurate physiology and function of joints in total hip replacement.

Watch a video of Sawbones hip patient demonstrators here.

Total Hip Replacement Procedures

Hip joint models can help educate both patients and medical students on the following total hip replacement and related procedures:

Total Hip Replacement (Traditional) |

Total hip joint models show the range of hip motion prior to and following surgery, demonstrating the rationale of the operation. The depiction of the pelvis and femur in the model helps learners visually grasp how much bone is removed in the process. Removable parts also show the functional use of total joint implants and give an idea of their typical shape and size. |

Total Hip Replacement (Anterior) |

A full hip joint model is very useful in explaining how an anterior approach presents certain advantages over a traditional total hip replacement. Its benefits include:

On the other hand, surgeons can also use hip joint models to explain why this approach may not work for everyone. For example, muscular or obese patients are not ideal candidates for an anterior approach as they require longer incisions. Patients with wide pelvises and those who have hip implants from prior surgery are also not suited for an anterior approach for similar reasons. |

Hip Arthroscopy |

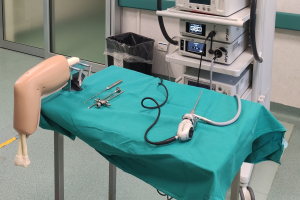

In preparation for total hip replacement surgery, patients may need to undergo a preliminary hip arthroscopy. A hip joint model shows how a tiny camera or arthroscope works together with small surgical tools to examine a damaged hip joint. Using the model, surgeons can emphasize that hip arthroscopy is a minimally invasive procedure. |

Total Hip Replacement Revision |

Though total hip replacement has a high rate of success, certain cases may necessitate revision surgery. Common causes include:

A hip joint model can illustrate how these factors undermine the effectiveness of the original procedure and what options are available to restore or at least improve function. |

Comprehensive Training with Hip Joint Models

Medical Sales College, a leading training institution for medical device sales, uses Sawbones’ high-quality hip joint models to provide students with a comprehensive understanding of anatomy and device design in hip surgeries. Its course on sports medicine and orthopaedic reconstruction and trauma includes a week-long focus on total knee and total hip arthroplasty.

Student Heidi Brown shares, “We learned a lot from how to build relationships in the OR, how to sell, the proper do's and don'ts in the OR setting. We learned a lot about the human anatomy all the way down to hip, knee, shoulder, and trauma surgeries.” Fellow student Brittany Mader also said, “In addition to this, [Sawbones] labs were demonstrated allowing me to get hands-on experience with hardware and implants as well as product presentations weekly and role plays.”

Using hip joint models, students become better acquainted with the biomechanics at work in total hip arthroplasty. Medical models also help trainees appreciate the difference between bipolar hip arthroplasty, total hip replacement, and revision total hip replacement surgery—among others. Lastly, familiarization with the range of hip joint implants available and how they improve hip motion gives trainees a leg up in the medical device sales market. In combination, these benefits ultimately improve patient outcomes and set medical trainees up for success in the field.

Sawbones offers best-in-class hip joint models for medical demonstration and patient education. Known for originating hands-on workshop models, Sawbones continues its leadership in the manufacturing of anatomical medical training models. For more information on our offerings or to talk about custom training models, contact us at 206-463-5551.

If you're seeking something you can't find on our website, our sales team is happy to help. We can either direct you to the right model or provide a free quote on the right custom project to meet your needs. Discover options with our clear bone models, laminated blocks, custom displays, or other machining projects.