Sawbones Showcase: Arm Bone Models Casting Through Repetitive Practice

Mastery of technical skill in orthopedics and medical surgery demands extensive training and repetition. Repetitive practice helps students acquire and perfect technique. Constant exercise of technical knowledge also aids practitioners in maintaining competence and combating skill decay. The use of high fidelity models in procedural skill practice can help facilitate continual training in the orthopedic and medical community in general.

Arm casting in particular is a key technical skill requiring repetitive practice. Improper casting can cause complications such as poor blood circulation, pain, inefficient immobilization, and an even higher risk of morbidity. On the other hand, proper casting techniques produce the desired therapeutic effect of the fracture treatment. An excellent way to train these casting techniques is with the help of innovative arm bone models from Sawbones.

Arm Bone Models Offer Lifelike Conditions for Training Casting Techniques

Arm bone models provide students with superior hands-on experience for repetitive practice of casting techniques compared to the use of organic models or digital simulation. While virtual learning environments feed more information to users, the use of physical models encourages creative thinking and allows greater freedom for individual styles of learning. In other words, students and trainees master important technical skills at their own pace. Synthetic models also remove emotional and social barriers that may be present when using organic models.

High-quality models are desirable for repetitive use both for individual and group practice. Moreover, arm bone models are easily accessed anytime, anywhere compared to organic models or digital tools which require additional setup.

Some scenarios where arm bone models prove most useful for repetitive practice of upper extremity casting include:

Short and Long Arm Casting |

Arm bone models in a neutral position with the forearm, elbow, wrist, and hand aligned in a straight line are best for practicing basic types of arm casting. These include:

With a full arm model, students can learn and apply proper methods of rolling and molding for all three of these casting types. Correction of soft spots and molding errors is also better facilitated using hands-on models compared to simulation and digital tools. Synthetic models help students immediately assess their technique regarding appropriate padding coverage and reinforcement. |

Thumb Spica and Ulnar/Radial Gutter Casting |

Arm bone models with detailed anatomical parts are invaluable in the repetitive practice of thumb spica and ulnar or radial gutter casting. Hand and wrist models guide students in perfecting their technique in proper cast positioning and application between relevant fingers and joints. The complementary use of bone models is also useful for highlighting sensitive areas in the wrist and hand that must be given extra attention in these types of casts. Anatomically accurate replicas of the radius, ulna, metacarpals, phalanges, etc. reinforce the importance of proper immobilization for successful fracture treatment. |

Cast Variations |

Other arm casting variations including Muenster’s cast and boxer’s cast can be practiced on relevant arm bone models. Cast conversions such as cutting a long arm cast into a short arm cast can also be facilitated. Additional casting modifications can be practiced to acquaint students with the variety of techniques available. These include:

|

Cast Removal |

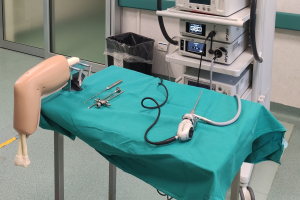

Arm models are also excellent tools for practicing cast removals. Splitting or removing casts necessitates dexterous handling of a cast saw with a special oscillating blade. Familiarity with this instrument is essential not only for proper cutting but also to assuage patients’ fear or discomfort. Lack of training in cast removal can result in improper technique such as dragging the blade through the cast or direct application over bony areas, resulting in wounds and burns. Repetitive practice using arm bone models prepares students to deal with risk factors such as heat and friction in a safe yet hands-on environment. |

Effective Training with Arm Bone Models Casting

Arm bone models facilitate effective repetitive training for mastery of upper extremity casting through hands-on learning, physical interaction, and encouragement of creative thinking as well as critical thinking. It also provides students a safe environment to correct mistakes and anticipate risk factors in different arm casting scenarios.

Medical schools and facilities benefit from the use of arm bone models for orthopedic procedural training. One example is Medical Sales College, where medical sales trainees learn orthopaedic procedures for trauma, fractures, and other injuries. Student Mikayla McDonald shared, “At Medical Sales College we covered the orthopaedic reconstruction procedures (total hip, knee and shoulder arthroplasty) in great detail. We spend numerous days going through detailed powerpoints, watching videos of cases, and practicing the procedural steps with sawbones.”

The school also teaches students the challenges of the initial trauma and fracture treatment as well as how to best utilize the array of devices (i.e. splints and casts) available. Having hands-on experience through repetitive practice equips trainees and students with greater insight and sets them up for success in their chosen medical field.

Sawbones offers best-in-class arm bone models for upper extremity casting. Known for originating hands-on workshop models, Sawbones continues its leadership in manufacturing medical models for orthopedic and medical education. For more information on our offerings or to talk about custom training models, contact us at 206-463-5551.

If you're seeking something you can't find on our website, our sales team is happy to help. We can either direct you to the right model or provide a free quote on the right custom project to meet your needs. Discover options with our clear bone models, laminated blocks, custom displays, or other machining projects.