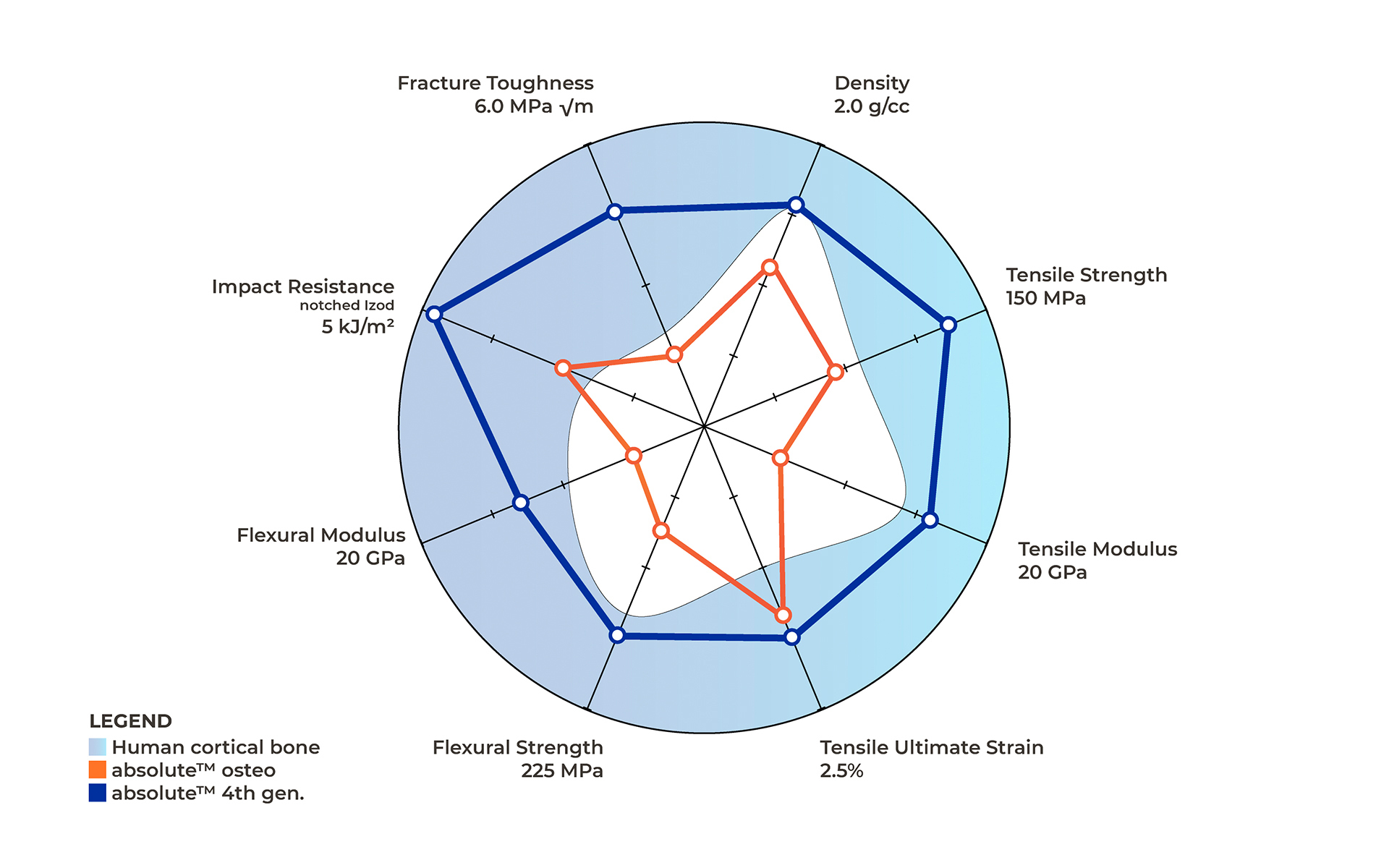

Sawbones’ unique epoxy formulation is filled with short glass fibers and used to simulate cortical bone for structural testing of fixation devices and total joint replacements. Our simulated cortical bone has a density, fracture toughness, strength, modulus and hardness all similar to cadaveric cortical bone.

This material is the cortical bone for all our absolute™ bones.

| PHYSICAL PROPERTY | absolute™ 4th GEN. | absolute™ OSTEO | UNITS | TEST METHOD | |

|---|---|---|---|---|---|

| Density | 102 | 82 | pcf | ASTM D792 | |

| 1.64 | 1.31 | g/cc | |||

| Hardness | 92 | 90 | Shore D | ASTM D2240 | |

| Tensile Modulus | Longitudinal | 16 | 5.4 | GPa | ASTM D638 |

| Transverse | 11 | isotropic | GPa | ||

| Tensile Strength | Longitudinal | 130 | 70 | MPa | |

| Transverse | 96 | isotropic | MPa | ||

| Ultimate Tensile Strain | Longitudinal | 1.9 | 1.7 | % | |

| Transverse | 1.5 | isotropic | % | ||

| Flexural Modulus | 12 | 5.1 | GPa | ASTM D790 | |

| Flexural Strength | 145 | 81 | MPa | ||

| Poisson Ratio | 0.26 | 0.26 | |||

| Compressive Strength | 167 | 147 | MPa | ASTM D695 | |

| Fracture Toughness, KIC | 4.6 | 1.5 | MPa M1/2 | ASTM E399 | |

| Impact Strength, Notched Izod | 48 | 25 | J/m | ASTM D256 | |

| Impact Resistance, Notched Izod | 4.7 | 2.5 | kJ/m2 | ||

| absolute™ SHEET/CYLINDER TOLERANCES: | |

|---|---|

| Density | ±2.5% |

| Length and Width | ±2mm |

| Sheet/Wall Thickness | ≤ 2mm = ±0.2mm > 2mm = ±0.3mm |